Process blood and avoid contamination

Processing blood has always been one of the major environmental issues for slaughter lines around the world.

Traditionally, many plants have dealt with the challenge of recyclable water, which in some American countries meant rivers of blood in those places close to the facilities with the consequent social and environmental impact or odors generated in the oxidation bags.

The purification of the water in more modern and technical facilities, transferred the problem due to the high cost of purifying the water or blood.

There are two solutions to these problems:

- The collection of blood for use in food processing or for the pharmaceutical industry. This requires a strong investment in equipment after which the industrialist is at the mercy of the strong bargaining power of the company that withdraws his liquid blood.

- Dehydrate the blood for sale as blood meal to rendering or use companies. With this solution it has been shown that it is easier and more profitable to solve this problem.

How to process blood by dehydration?

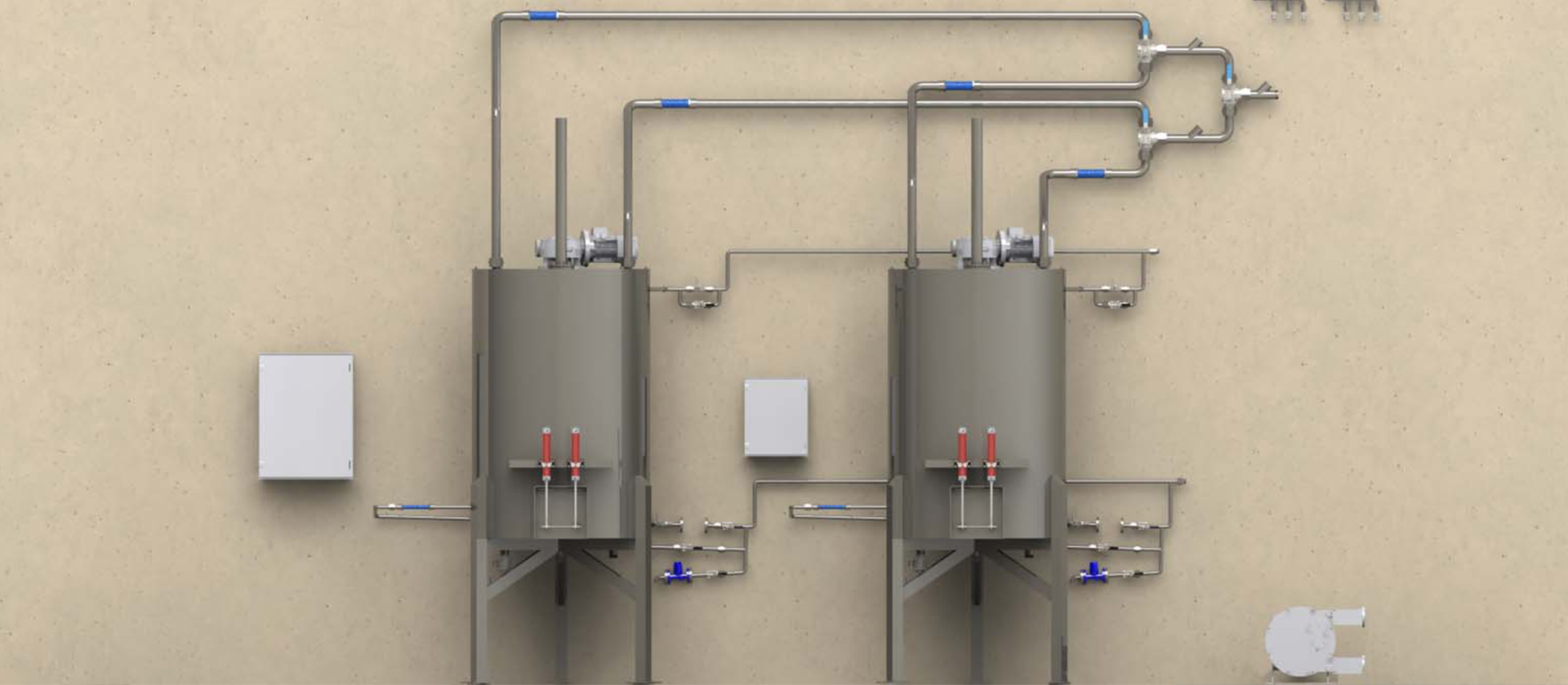

The system consists of collecting all the blood in the blood tank, cooking it in a blood cooker and separating the whey (liquid similar to water) from the blood meal. This product, already in a solid state with a humidity percentage between 30 or 40%, can be marketed to rendering companies for the production of feed as protein from animals of different species.

This solution means obtaining profitability through the sale of this flour while eliminating the problem of contamination in the treatment plant. Considering that there are several possible buyers and the control of the product, already in a solid state, it is much easier to store and market.

These cooking equipment are very easy to install and operate and require minimal maintenance. There is even more advanced equipment for the treatment of blood.