New shipment of Beef Rail Trolley to the USA: How the plastic is key for the wheels

Mecanova has sent a new shipment of 300 beef rail trolleys to a slaughterhouse in Oklahoma, in the USA.

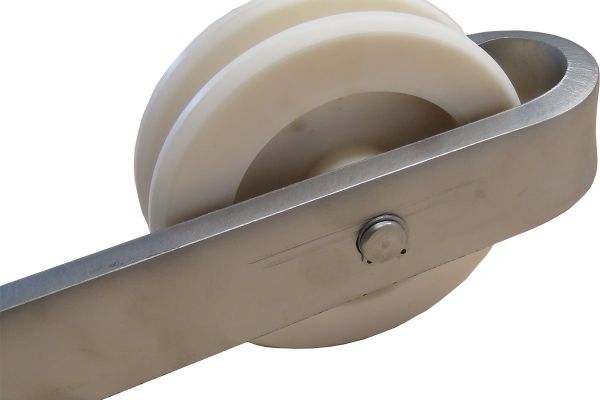

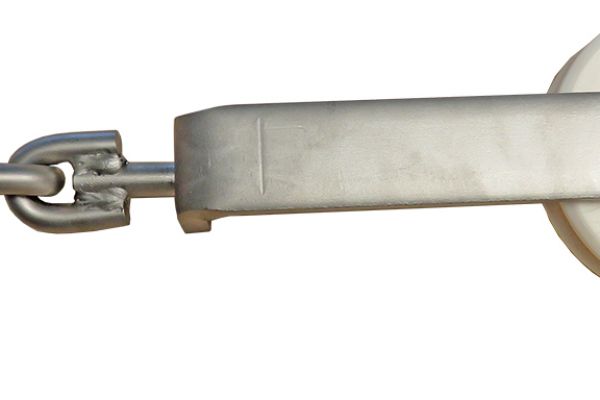

This very week week, directly from our workshop, a shipment of 300 beef rail trolleys straight to a slaughterhouse in Chickasha, Oklahoma in the United States. The order has been manufactured according to the dimensions and weights requested by our client. The trolleys are made of stainless steel, with a food-grade plastic wheel. It also incorporates our twist Eurohook, made of stainless steel with a rotating reinforcement piece to improve thepiece movement on the track.

Thanks to this equipment, our client in Oklahoma will be able to implement their production in their cattle and sheep slaughterhouse. The flat wheel or carriage manufactured by Mecanova incorporates a novel element that is the food-grade plastic wheel, which will significantly optimize the transfer process due to its durability, resistance and good rolling.

FOOD PLASTIC WHEEL, The key element

Mecanova has incorporated in its design of the beef rail trolley, the food-grade hard plastic to make the wheel of the trolley, thus differentiating itself from the traditional ones. This type of material means a better sliding of the wheel on the track, as well as an increase in the quality of the carcass, because with this material the possibilities of dirtying the meat due to metal splinters are reduced.

What is the difference? Traditional beef rail trolleys tend to have some disadvantages due to their material. Conventional wheels are metallic and roll on metal plates, and this causes the precipitation of metal chips on the meat. They also have a high weight, which can sometimes mean a trolley weight of 6 kg and it can compromises the working health of the operators who manage the work of hanging channels. Traditional trolleys, on the other hand, are made of iron, and this requires daily cleaning and lubrication, which translates into time spent on proper cleaning, lubrication, and movement to meet standards.

Given this, it is important to update and improve the preparation materials to achieve better results. The stainless steel rail trolleys designed and manufactured by Mecanova are an advantage for the transfer and storage of carcasses. Using high hardness and density food-grade plastic wheels keeps the properties and resistance expected of this type of trolley, and at the same time it eliminates the risk of metal splinters falling onto the carcass. This adds to the advantage that this material does not require lubrication. Another advantage is the significant reduction in weight: the plastic wheel reduces the weight of the roller by up to 2.6 kg per unit. This means better productivity and occupational health of the operators. In addition, the AISI - 304 stainless steel structure allows automatic cleaning of empty return conveyors, always presenting optimal hygienic and heatlhy conditions.

Manufacturers of trolleys and slaughterhouse material in general must have as a principle the study and testing of the best materials, with the ultimate goal of ensuring the production of their customers. Technology, the safe combination of materials and good design meanss the best results in the big picture, both for customers and manufacturers. With this goal as a priority, the maximum quality of the final product is assured.